Sustainability InitiativesReduction of Pollutant Emissions and Effective Use of Resources

We handle a wide variety of chemical substances, which we manage thoroughly in order to reduce environmental risks.

We also promote the 3Rs (Reduce, Reuse, Recycle) to reduce waste and promote effective use of resources.

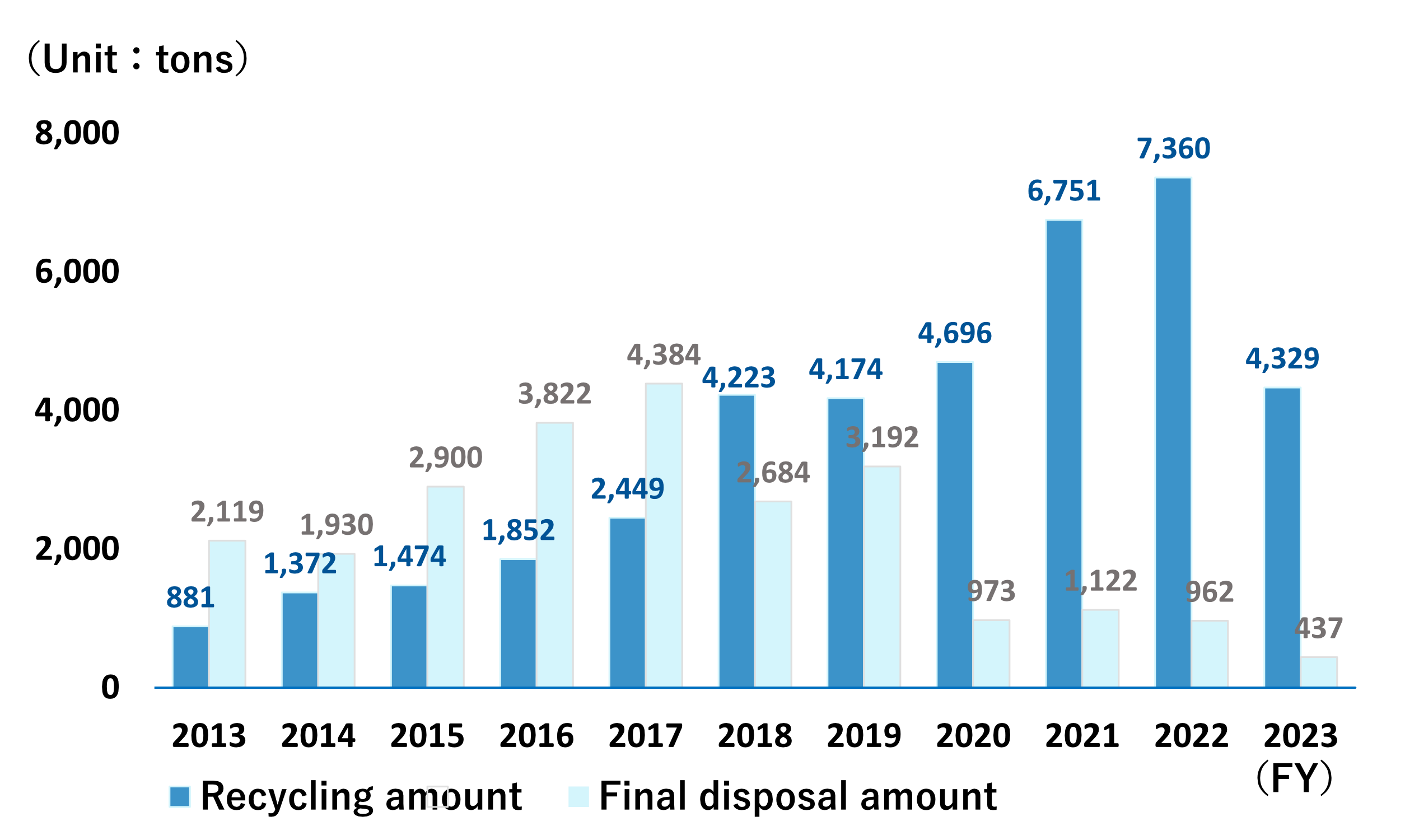

Reduction of the Final Disposal of Industrial Waste

From FY2018 onward, we have promoted the recycling of waste generated to reduce the final disposal of industrial waste. In FY2023, in addition to a decrease in industrial waste emissions due to reduced production volume, we were able to improve the industrial waste recycling rate, achieving a 60.1% reduction compared to FY2021.

Going forward, we will consider specific measures to recover resources from waste, and we will work to reduce waste itself by building facilities for this purpose.

The 9th RC Action Targets

- Target: Reduce final disposal of industrial waste by 9% compared to FY2021 by improving the recycling rate (3% reduction per year).

- Result: 60.1% reduction in FY2023 compared to 2021

Amount of industrial waste treated

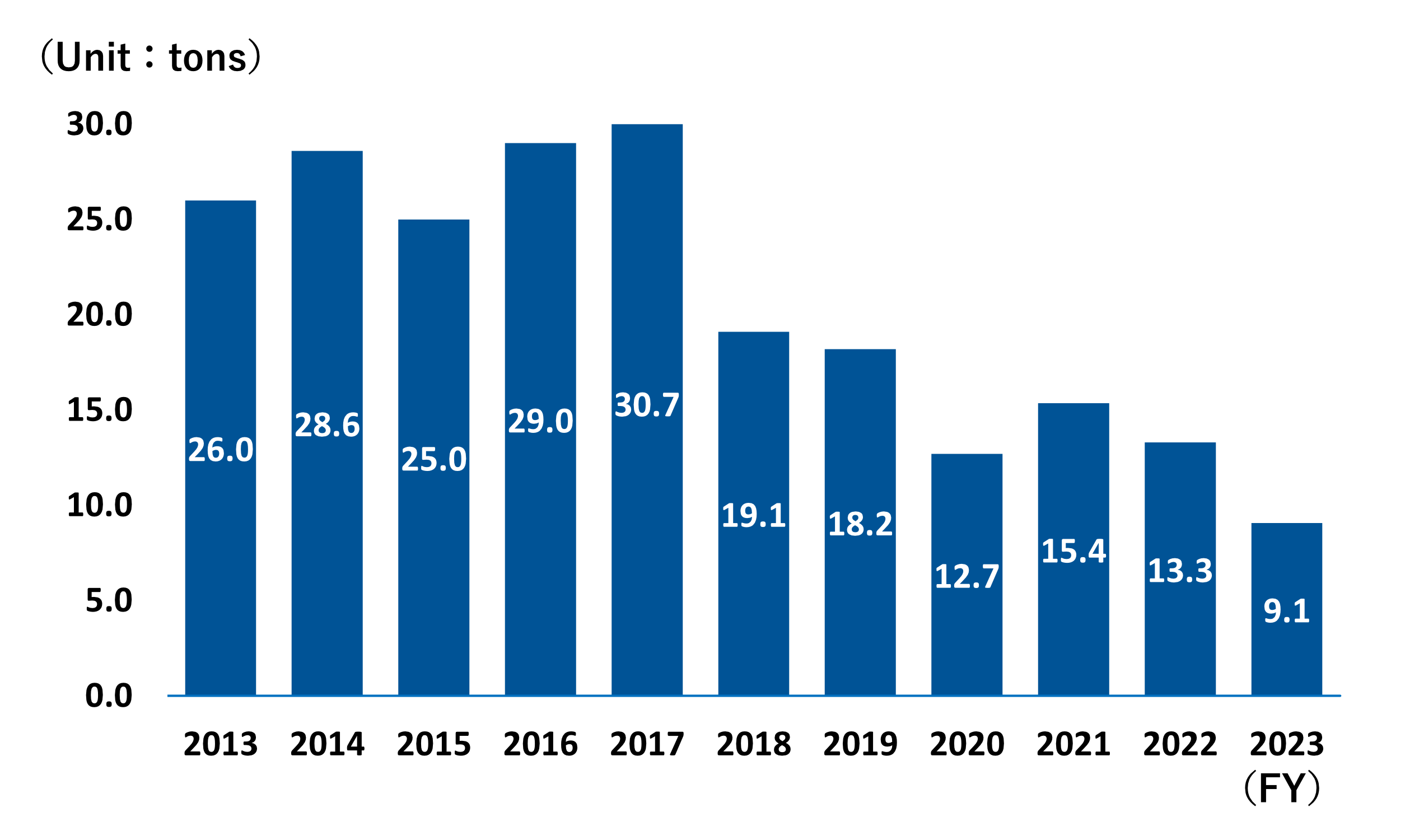

Reduction of Emissions of PRTR Target Substances

In accordance with the Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement, businesses are obligated to monitor and report to the government the amount of chemical substances released or transferred, and Kanto Denka Kogyo uses the JCIA method* to manage the chemical substances we handle. In FY2023, the number of PRTR target substances that we handled was 30, and the amount handled decreased by 33.3% compared to FY2021 to 166,000 tons due to the reduction in the production of chlorine-based solvents, and emissions into the environment decreased by 40.7% to 9.1 tons. This equates to 55 grams of unit emissions per ton handled.

*The JCIA method covers a greater number of substances than PRTR target substances under the law and requires more stringent management.

The 9th RC Action Targets

- Target: Reduce emissions of PRTR-designated chemical substances under the JCIA method by 3% compared to FY2021 (1% reduction per year).

- Result: 40.7% reduction in FY2023 compared to FY2021

Emissions of PRTR target substances

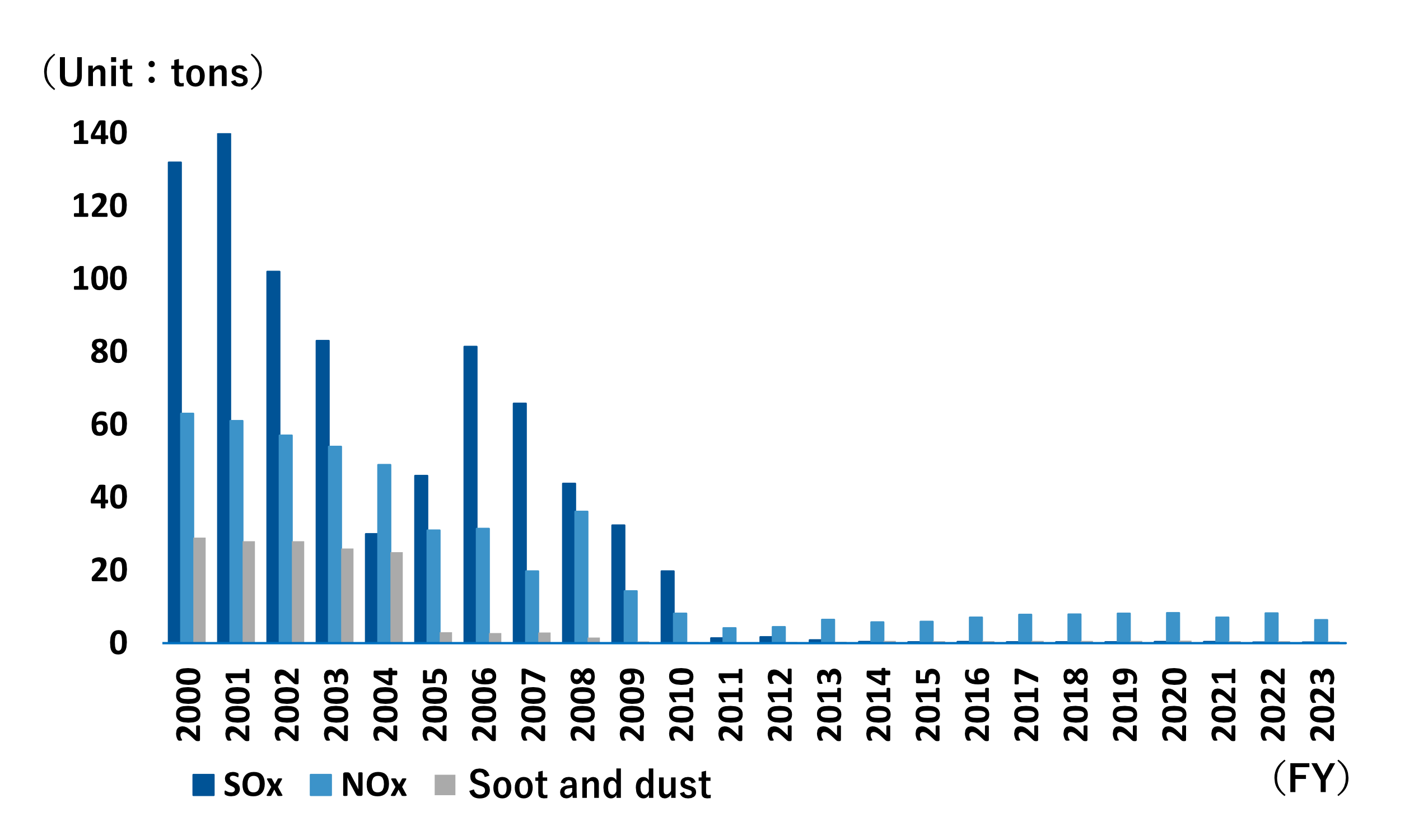

Reduction of Emissions of Air Pollutants

We are working to reduce the emissions of atmospheric pollutants, namely SOx (sulfuroxides), NOx (nitrogen oxides) and Soot and Dust through fuel conversion and stable operation of abatement equipment. Going forward, we will continue to enhance facility management and operations management so that we can maintain low emissions levels.

Emissions of air pollutants

[Emissions of air pollutants]

| FY2021 | FY2022 | FY2023 | |

|---|---|---|---|

| SOx | 0.41 | 0.28 | 0.25 |

| NOx | 7.11 | 8.21 | 6.43 |

| Soot and Dust | 0.58 | 0.53 | 0.48 |

Reduction of Water Pollutant Emissions

To prevent environmental impact, we conduct thorough wastewater management based on in-house standards that are stricter than those stipulated by environmental laws and regulations.

[Amount of pollutants in wastewater]

| FY2021 | FY2022 | FY2023 | |

|---|---|---|---|

| COD | 22.57 | 23.73 | 21.08 |

| Total nitrogen | 22.49 | 23.76 | 12.39 |

| Total phosphorus | 0.92 | 0.92 | 0.83 |

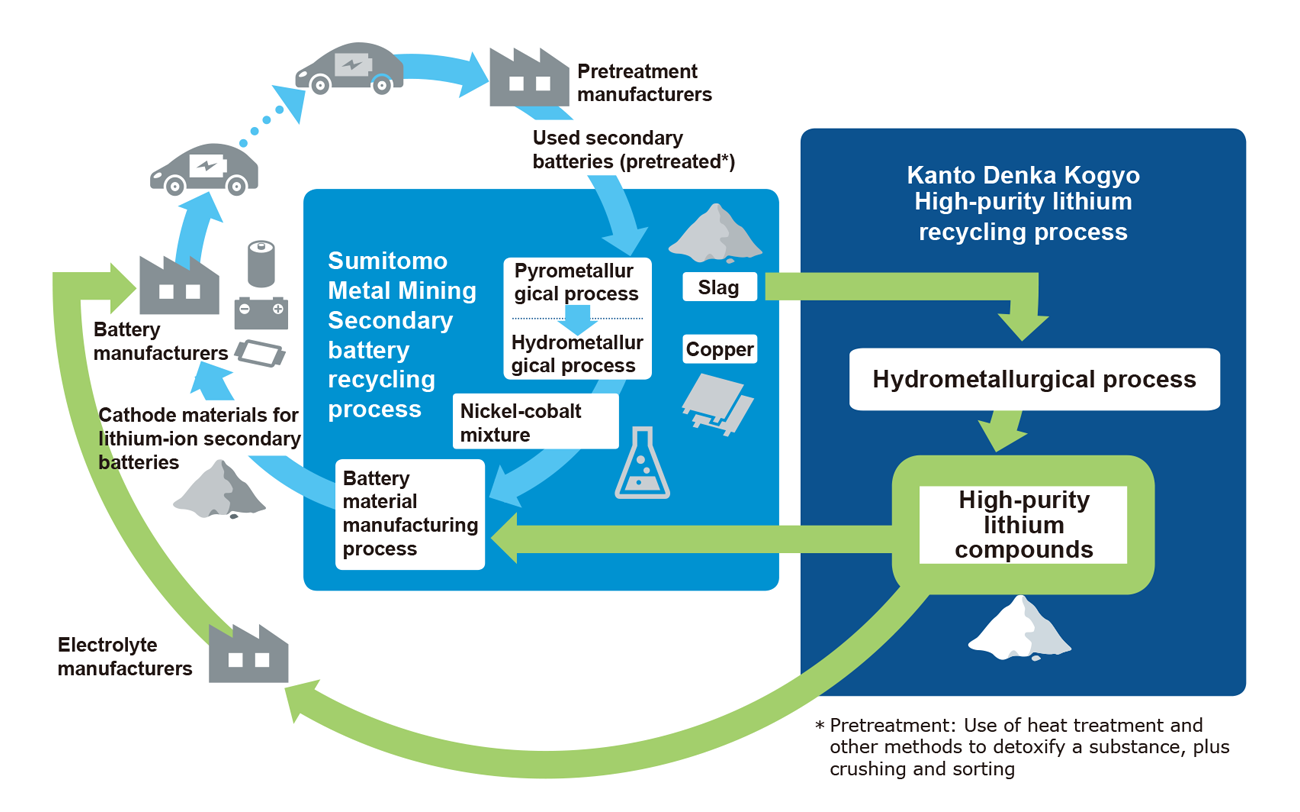

Initiatives for the effective use of resources

Through joint development with Sumitomo Metal Mining, Co., Ltd. (“Sumitomo Metal Mining”), we have established the world’s first technology to recycle lithium compounds from used lithium-ion secondary batteries (“LIBs”) with high-purity and to recycle them horizontally into battery materials.

【Process for recycling high-purity lithium compounds from used LIBs】

Together with Sumitomo Metal Mining, we proposed and adopted the “Development and Demonstration of a Storage Battery Recycling Process” (the “Project”) for the “development of technology for storage battery recycling,” which is one of the research and development items of the “Green Innovation Fund / Next-generation Storage Battery and Motor Development” project announced by the New Energy and Industrial Technology Development Organization (“NEDO”). The Green Innovation Fund project aims to achieve carbon neutrality by 2050, with the Ministry of Economy, Trade and Industry creating a two trillion yen fund for NEDO to continue to support companies committed to ambitious goals for 10 years, from research, development, and demonstration to social implementation. The “Next-generation Storage Battery and Motor Development” project aims to achieve decarbonization and industrial competitiveness in the automotive sector by conducting research and development related to high performance, resource saving, and recycling of storage batteries and motors. In the Project, we aim to create and expand a horizontal recycling business that recovers copper, nickel, cobalt, and lithium from spent lithium-ion batteries and other secondary batteries using the non-ferrous metal smelting technology of Sumitomo Metal Mining and our lithium recovery technology. We will contribute to achieving a sustainable society through the realization of this project.