Sustainability InitiativesResponse to Climate Change

In support of Agenda 21: Global Plan of Action for Sustainable Development, adopted at the United Nations Conference on Environment and Development, we are promoting responsible care (RC) activities, a voluntary initiative to implement and improve comprehensive safety measures for chemical substances.

It is the responsibility of a company to ensure that its corporate activities do not affect the environment of surrounding areas and the entire planet, and we will implement voluntary management activities to implement and improve safety, health, and environmental measures throughout the entire life cycle of chemical substances, from development through manufacturing, distribution, use, and final consumption to disposal.

RC Basic Philosophy

Recognizing that the preservation of the global environment is one of the common challenges facing humankind, we will, based on our own responsibility in our corporate activities, give consideration to the preservation of the environment and safety throughout the entire lifecycle of our products, from development through manufacturing, distribution, use, and disposal.

RC Basic Policy

- 1.Carry out comprehensive environmental and safety management in such areas as environmental protection, operational safety and disaster prevention, occupational health and safety, chemical product safety, logistics safety, and international trade safety.

- 2.Ensure the safety of employees and areas in the vicinity of company facilities by working to achieve zero accidents and zero disasters.

- 3.Make efforts to save energy and resources and reduce the amount of industrial waste generated as a result of operations.

- 4.Ensure the development and introduction of products and manufacturing processes that take environmental and safety issues into account.

- 5.Strictly comply with laws, regulations and agreements related to the environment and safety, as well as establish and meet our own stricter voluntary standards in these areas.

- 6.Promote logistics safety and safe chemical handling for customers.

- 7.Carry out the Environmental and Safety Audits.

- 8.Collect information on the environment and safety related to products, and thoroughly disseminate the information among employees and provide information to customers.

- 9.Take care to ensure the protection of the environment and safety in overseas operations, technology transfers and the international trade of chemical products.

- 10. Promote mutual understanding of risk by widely publicizing the details and results of our environmental and safety activities to local communities, investors, related organizations and others through environmental reports and other materials.

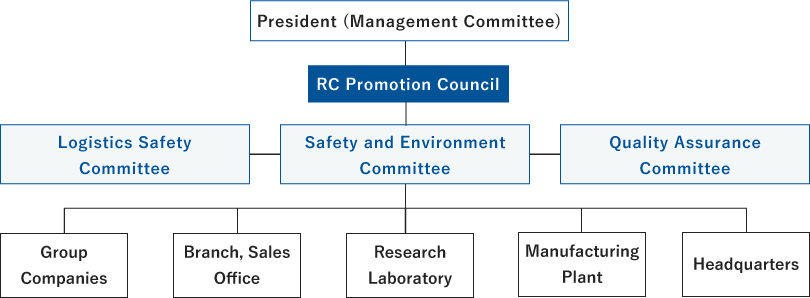

RC Promotion System

RC Promotion Council

The RC Promotion Council is chaired by the President and consists of the chairpersons of its committees and a few members appointed by the President. With the Safety & Environment Department serving as the secretariat, the Committee is responsible for formulating RC policies for each fiscal year and over the medium- to long-term, deliberating and deciding on important issues related to company-wide RC activities, overseeing three committees, and discussing and coordinating RC promotion and audit issues.

The 9th RC Action Targets (Three-year plan from FY2022 to FY2024)

We took the following measures to achieve the 9th RC Action Targets:

- 1Actions for zero accidents and zero disasters:

- 2Energy-saving measures:

- 3Reduction of final landfill disposal amounts of industrial waste:

- 4Reduction of emissions of PRTR target substances:

- 5Reduction of greenhouse gases emissions:

Strengthen safety measures by effectively using the PDCA cycle based on the 5S (Sort, Set, Shine, Standardize, and Sustain) method

Foster improvements in the intensity of our high energy-consuming facilities and promote the effective use of excess hydrogen

Diversify recycling destinations and improve raw material consumption intensity to reduce the generation of industrial waste

Analyze the causes of increasing pollutants and enhance countermeasures

Implement measures to address detailed sources toward reducing emissions of substances with high global warming potential and power-conservation measures to cut CO2 emissions

Reduction of greenhouse gases

We produce various compounds from fluorine and chlorine obtained by electrolysis, and we consume a large amount of electricity to perform electrolysis. However, we aim to achieve carbon neutrality by 2050 and are committed to reducing CO2 emissions from energy sources by 50% from the FY2013 level by FY2030.

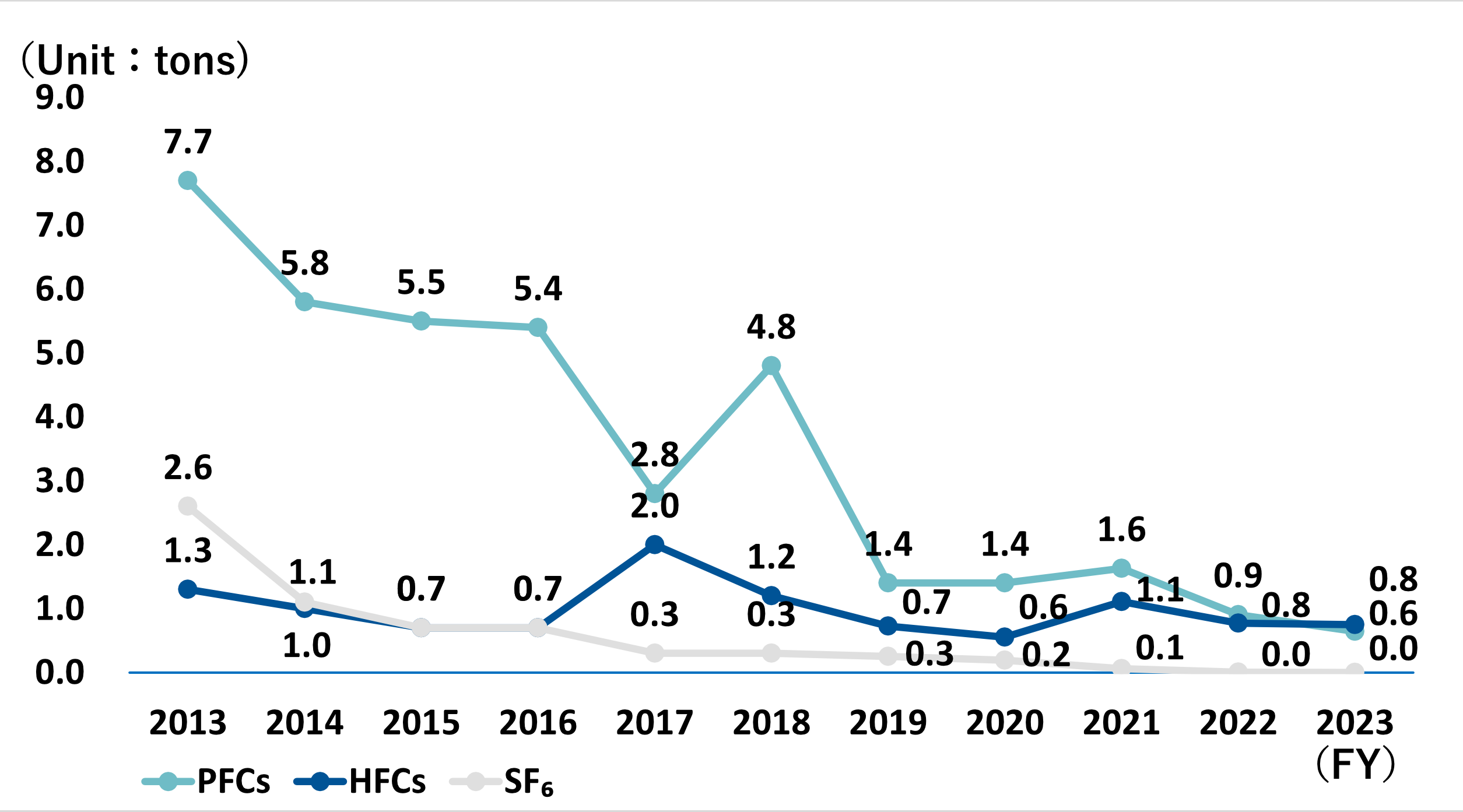

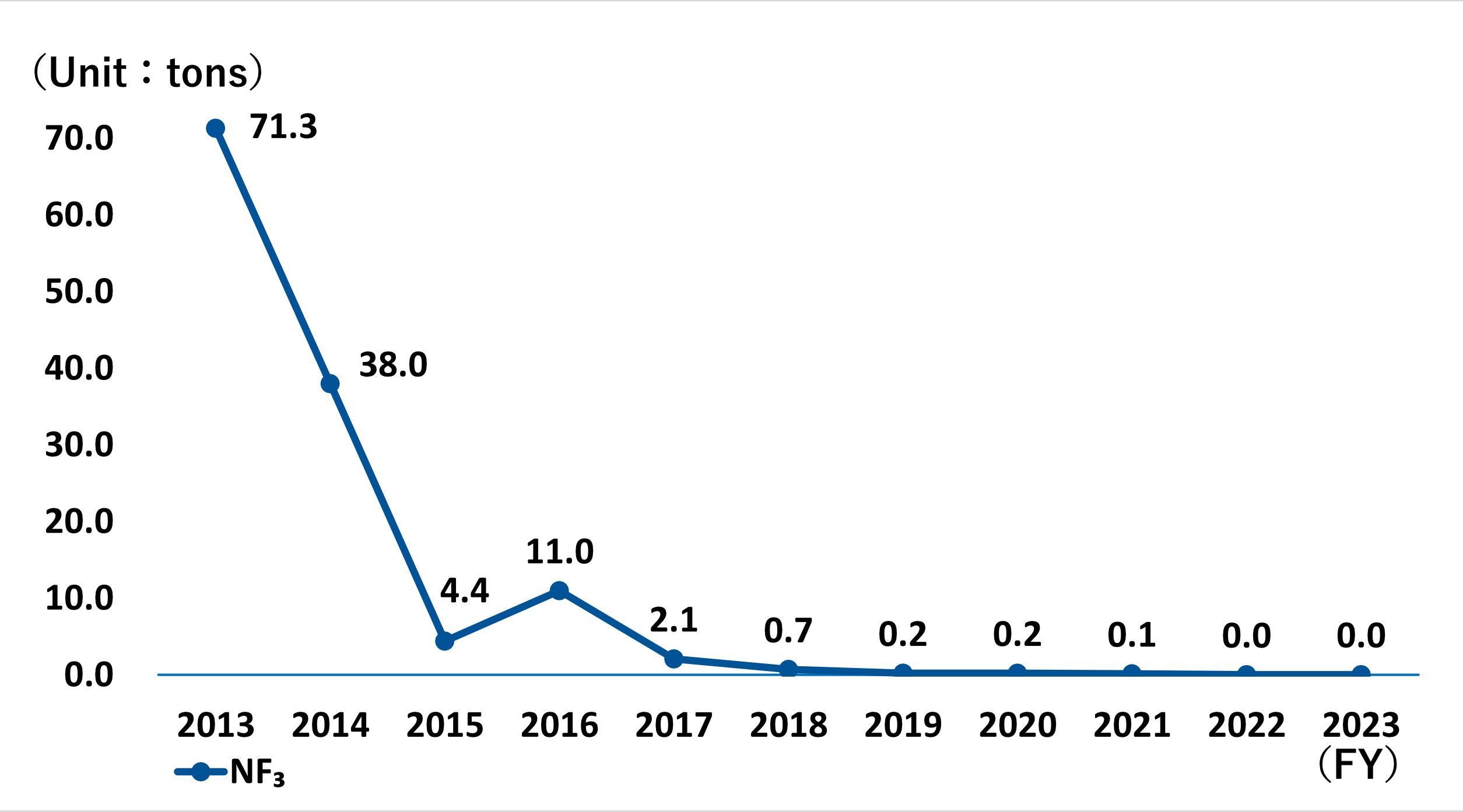

We have been working to reduce greenhouse gas emissions from non-energy sources since 2009 with the introduction of detoxification equipment, and have made significant progress, achieving a 99.5% reduction in FY2023 compared to FY2013. In FY2023, energy source greenhouse gas emissions decreased by 26.9% compared to FY2013, due to reduced production volume, lower emission factors from power utilities, and procurement of electricity with non-fossil fuel certificates. We have also reduced greenhouse gas emissions from our manufacturing processes, resulting in an overall 88.6% reduction in greenhouse gas emissions (CO2 equivalent).

We have calculated the amount of greenhouse gas emissions (Scope 3) throughout the supply chain, from the purchase of raw materials to their use and disposal by customers, and are working to reduce greenhouse gas emissions throughout the supply chain.

In FY2023, we installed solar power generation equipment at our Shibukawa and Mizushima Plants. We will further accelerate the reduction of greenhouse gas emissions by creating and using renewable energy while promoting energy conservation and improvements of energy per unit, and aim to achieve carbon neutrality by 2050.

The 9th RC Action Targets

- Target: Reduce CO2 equivalent greenhouse gas emissions by 6% compared to FY2021 levels (2% reduction per year).

- Result: 28.0% reduction in FY2023 compared to FY2021(88.6% reduction compared to FY2013)

Greenhouse Gas Emissions from Non-energy Sources

Emissions of PFCs, HFCs, and SF6

Emissions of NF3

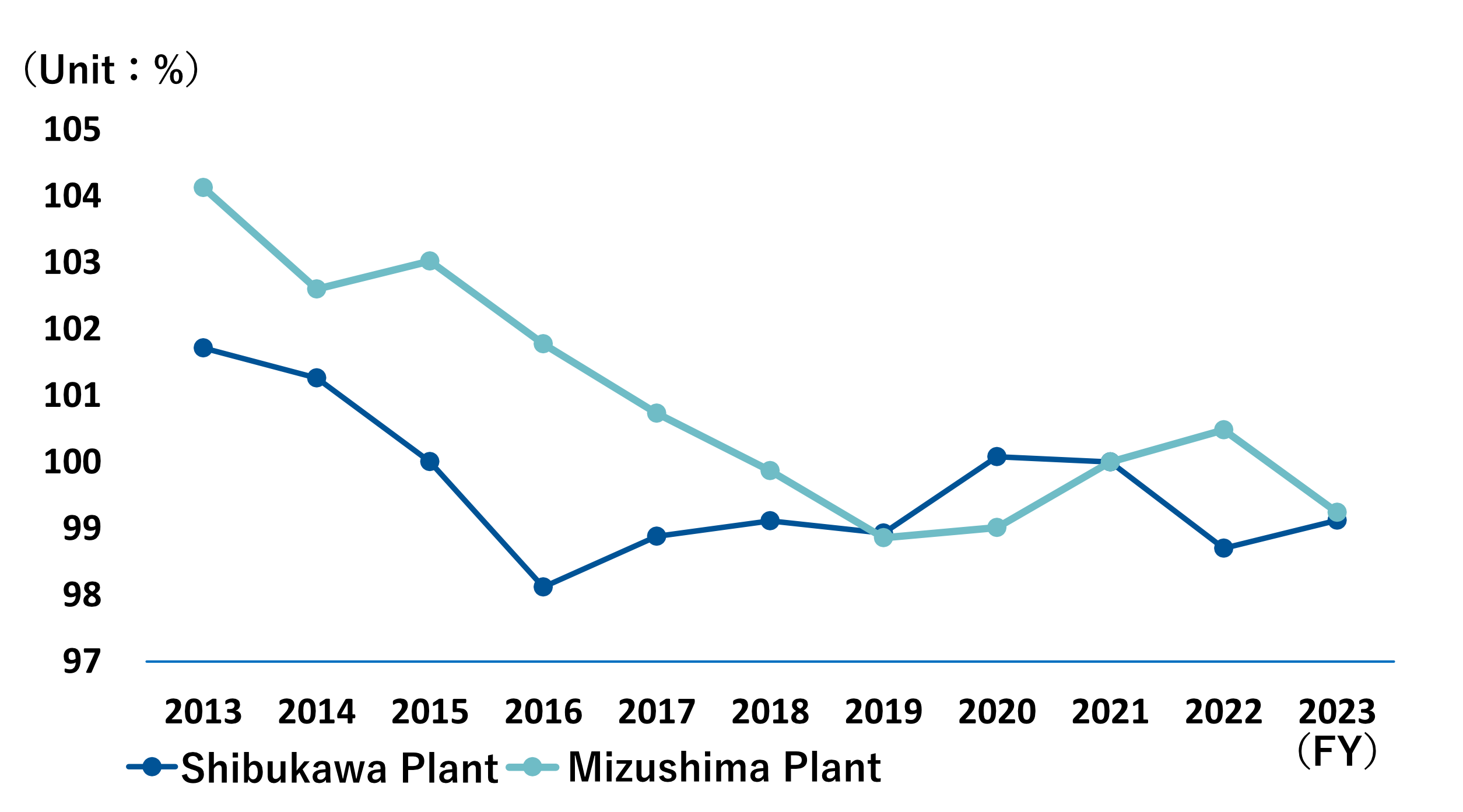

Improvement of Energy Consumption per Unit of Production

We continue to implement proactive activities such as improving power-hungry facilities and reducing steam intensity. In FY2023, we optimized the operation of electrolysis equipment and worked to improve unit consumption at the Mizushima Plant. Company-wide energy intensity was reduced by 2.2% compared to the base year due to decreased production and energy consumption at the Shibukawa Plant, which has high energy intensity. With an average improvement of at least 1% over five years, we achieved the non-binding goals set by the Energy Saving Act*.

*Act on Rationalization of Energy Use and Shift to Non-fossil Energy

The 9th RC Action Targets

- Target: Reduce energy consumption (crude oil equivalent) per factory production volume by 3% compared to FY2021 (1% reduction per year).

- Result: The Shibukawa Plant reduced its energy consumption per production volume by 0.9% and the Mizushima Plant reduced its consumption by 0.8% in FY2023 compared to FY2021.

Trends in energy consumption per unit of production

(Indicated with FY2021 as 100)